Lined Tee

VescoaT supplies and manufacturer of FEP / PFA Lined Equal Tee / Unequal Tee of various Standard, Non Standard size on Request, We also manufactures in PFA / FEP / HDPE lined Tee as per international standard of ASTM F1545.

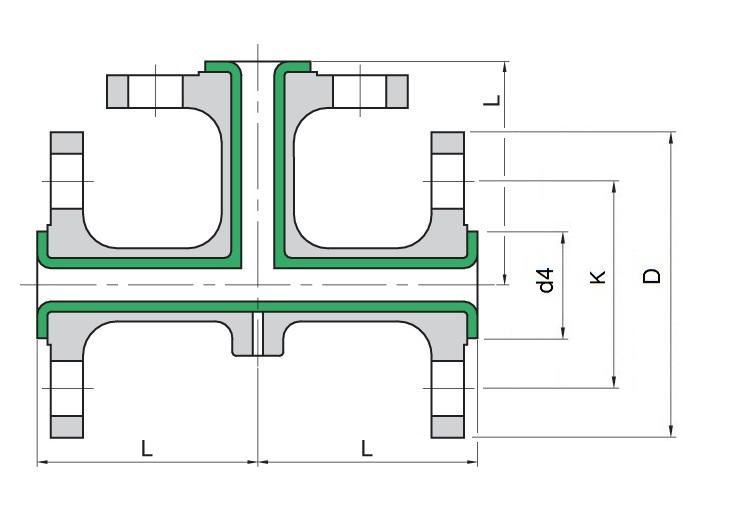

| Dimension Detail: | All Dimensions are in mm | ||||||

| NB | Centre Line to Face (L) mm | d4 | K | D | B1 | No. of Holes & Hole Dia | |

| MM | INCH | ||||||

| 15 | 1/2″ | 65 | 35.1 | 60.5 | 88.9 | 11.1 | 4 x 15.9 |

| 20 | 3/4″ | 75 | 42.9 | 69.9 | 94.4 | 12.5 | 4 x 15.9 |

| 25 | 1″ | 89 | 50.8 | 79.2 | 108 | 14.5 | 4 x 15.9 |

| 40 | 1.5″ | 102 | 73.2 | 98.6 | 127 | 17.5 | 4 x 15.9 |

| 50 | 2″ | 114 | 91.9 | 120.7 | 152.4 | 19.5 | 4 x 19.0 |

| 65 | 2.5″ | 127 | 104.6 | 139.7 | 177.8 | 22.2 | 4 x 19.0 |

| 80 | 3″ | 140 | 127.0 | 152.4 | 190.5 | 24.0 | 4 x 19.0 |

| 100 | 4″ | 165 | 157.2 | 190.5 | 228.6 | 24.0 | 8 x 19.0 |

| 150 | 6″ | 203 | 215.9 | 241.3 | 279.5 | 25.5 | 8 x 22.2 |

| 200 | 8″ | 229 | 269.7 | 298.5 | 342.9 | 29.0 | 8 x 22.2 |

| 250 | 10″ | 279 | 323.9 | 362.0 | 406.4 | 30.5 | 12 x 25.4 |

| 300 | 12″ | 305 | 381.0 | 431.8 | 482.6 | 32.0 | 12 x 25.4 |

Technical Specification:

| Size | 15NB TO 300NB ( ¾” TO 12” ) |

| Length | As per Standard of B16.5 & ANSI B 16.42 |

| Liner | PFA – Per Fluoro Alkoxy, ASTM D3307

FEP – Fluorinated Ethylene Propylene, ASTM D2116 HDPE – As per Standard |

| Body | As per ASTM A 234 Gr. WPB / DI A395 / SS304 / SS316 ( Seamless) |

| Steel Housing | Carbon steel or Stainless Steel |

| Flanges | ASTM A 105 (N) / IS 2062 / ASTM A351 GR CF8 & CF8M |

| Drilling / Pressure | ASA 150# / 300# / DIN / Table – F |

| Dimensional STD | Tee : B16.5 & ANSI B 16.42

Flanges : ASME B 16.5 Lining Standard : ASTM F 1545 |

| Temperature | -29℃~200℃ |

| Vacuum | Full vacuum rated |

| Testing/Inspection | Mechanical Properties | ||||

| PTFE | PFA | FEP | |||

| Hydro Test | At 29 Bar, after lining | Tensile Strength, PSI (min) | 3500 | 3800 | 3000 |

| Spark Test | At 25 KV | Elongation, % (min) | 300 | 300 | 250 |

Notes:

- All TEE have SOFF flange both side Fix Flange (one end loose flange and fixed flange at the other end. Or Both Side Loose Flange as on Request) For A105 Flange: lap joint flange at one end and fixed flange at the other end.

- Suitable vent holes are provided for all fittings.

- All Fittings work will be supplied with suitable wooden end covers to protect the flare faces.

- Material test certificates will be provided for all raw materials

- The plastic liner flare will replace the raised face portion of the flange.