Lined Pipes Systems

VescoaT supplies PTFE Lined piping for the chemical, pharmaceutical and associated industries. The PTFE fluoropolymers are chemically inert having near universal corrosion resistance which we specifically use to convey the most corrosive and toxic processes in Chemical and Pharmaceutical plants around the world. It is also used in high purity applications and an alternative to exotic materials such as Hastelloy. VescoaT is the stock and manufacturing distributor on PTFE lined piping products. VescoaT also manufactures and supplies PFA / FEP / HDPE lined fittings by using most advance and innovative techniqes.

VescoaT has been designing, processing and manufacturing the highest quality paste extruded PTFE and PFA lined products for 10 years. Our products are acknowledged to international standard of ASTM F1545, We pride ourselves in offering high levels of customer service and high integrity products.

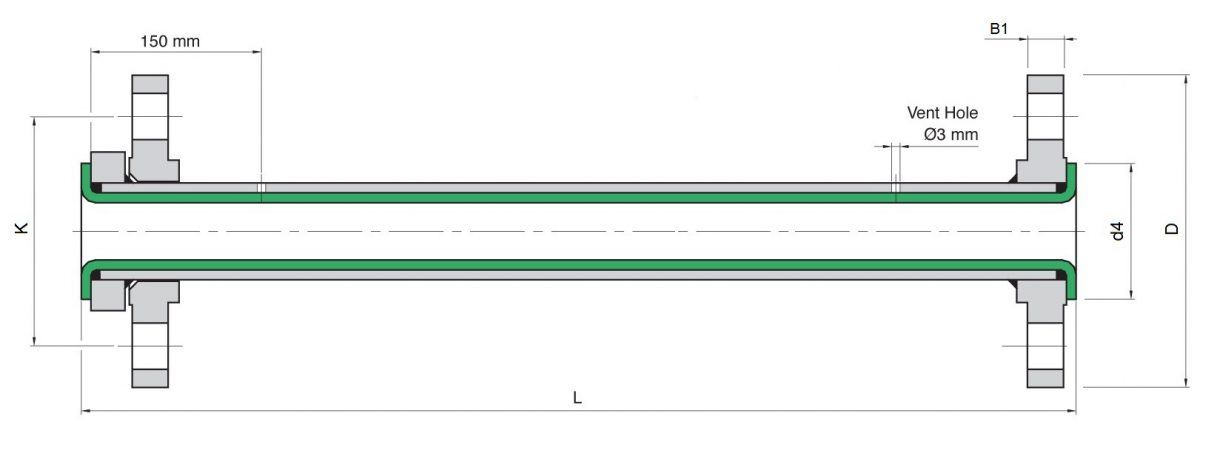

| Dimension Detail: | All Dimensions are in mm | ||||||||||

| NB | L (mm) | Lining

Thk. |

Pipe

Thk. |

d4 | K | D | B1 | No. of Holes & Hole Dia | |||

| MM | INCH | Max. | min. | ||||||||

| 15 | 1/2″ | 6000 | 65 | 2.5 | 2.77 | 35.1 | 60.5 | 88.9 | 11.1 | 4 x 15.9 | |

| 20 | 3/4″ | 6000 | 75 | 2.5 | 2.87 | 42.9 | 69.9 | 94.4 | 12.5 | 4 x 15.9 | |

| 25 | 1″ | 6000 | 75 | 3 | 3.38 | 50.8 | 79.2 | 108 | 14.5 | 4 x 15.9 | |

| 40 | 1.5″ | 6000 | 80 | 3 | 3.68 | 73.2 | 98.6 | 127 | 17.5 | 4 x 15.9 | |

| 50 | 2″ | 6000 | 90 | 3 | 3.91 | 91.9 | 120.7 | 152.4 | 19.5 | 4 x 19.0 | |

| 65 | 2.5″ | 6000 | 90 | 3 | 5.16 | 104.6 | 139.7 | 177.8 | 22.2 | 4 x 19.0 | |

| 80 | 3″ | 6000 | 90 | 3.5 | 5.49 | 127.0 | 152.4 | 190.5 | 24.0 | 4 x 19.0 | |

| 100 | 4″ | 6000 | 100 | 4 | 6.02 | 157.2 | 190.5 | 228.6 | 24.0 | 8 x 19.0 | |

| 150 | 6″ | 3000 | 100 | 5 | 7.11 | 215.9 | 241.3 | 279.5 | 25.5 | 8 x 22.2 | |

| 200 | 8″ | 1500 | 150 | 6 | 7.04 | 269.7 | 298.5 | 342.9 | 29.0 | 8 x 22.2 | |

| 250 | 10″ | 1000 | 150 | 6.5 | 9.3 | 323.9 | 362.0 | 406.4 | 30.5 | 12 x 25.4 | |

| 300 | 12″ | 1000 | 150 | 7.5 | 10.4 | 381.0 | 431.8 | 482.6 | 32.0 | 12 x 25.4 | |

Technical Specification:

| Size | 20NB TO 300NB ( ¾” TO 12” ) |

| Length | Upto 6000 mm |

| Liner | PTFE – Poly Tetra Fluoro Ethylene, ASTM D1457, D4894 and D4895

PFA – Per Fluoro Alkoxy, ASTM D3307 FEP – Fluorinated Ethylene Propylene, ASTM D2116 |

| Pipes | As per ASTM A 106 Gr. B,

Seamless Sch. 40up to 200NB & Sch. 30 for 250NB & 300NB |

| Steel Housing | Carbon steel or Stainless Steel |

| Flanges | ASTM A 105 (N) / IS 2062 / ASTM A351 GR CF8 & CF8M |

| Drilling / Pressure | ASA 150# / 300# / DIN / Table – F |

| Dimensional STD | Pipes : ANSI B 36.10

Flanges : ASME B 16.5 Lining Standard : ASTM F 1545 |

| Temperature | -29℃~200℃ |

| Vacuum | Full vacuum rated |

| Testing/Inspection | Mechanical Properties | ||||

| PTFE | PFA | FEP | |||

| Hydro Test | At 29 Bar, after lining | Tensile Strength, PSI (min) | 3500 | 3800 | 3000 |

| Spark Test | At 25 KV | Elongation, % (min) | 300 | 300 | 250 |

Notes :

- All pipes have SOFF flange both side with one end loose flange and fixed flange at the other end. For A105 Flange: lap joint flange at one end and fixed flange at the other end.

- Lined pipes are available up to a Length of 6 meters max.

- All fittings are supplied with fixed cast or welded flanges only.

- Suitable vent holes are provided for all pipes & fittings.

- All pipe work will be supplied with suitable wooden end covers to protect the flare faces.

- Material test certificates will be provided for all raw materials

- Weld buttons will be provided for pipe spools more than 300 mm long.

- The plastic liner flare will replace the raised face portion of the flange.